Cylindrical grinding is a precise and intricate process used in various industries to achieve high levels of accuracy and precision in the production of cylindrical components. This technique involves using a cylindrical grinding machine, which utilizes an abrasive wheel to remove material from a workpiece's surface and create the desired shape and dimensions. The process is widely employed in manufacturing sectors such as aerospace, automotive, medical, and tool making.

In this article, we will delve into the intricacies of cylindrical grinding by exploring its process steps, different types available, common applications across industries, as well as advantages and disadvantages associated with this technique.

Tight Tolerances

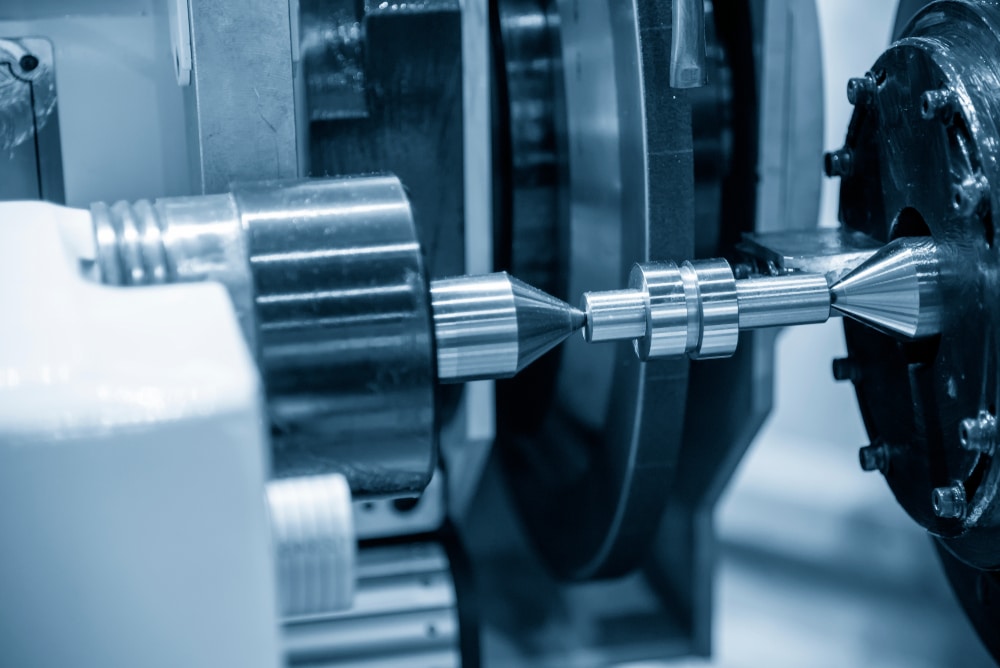

During cylindrical grinding, the workpiece rotates while being held between centers or in a chuck. Simultaneously, the grinding wheel traverses longitudinally along the length of the workpiece to remove material incrementally.

The precision achieved through this method allows for tight tolerances and smooth finishes on cylindrical surfaces.

Various types of materials can be processed using cylindrical grinding, including metals like steel, aluminum, and titanium alloys, as well as ceramics and composites.

Fundamental Principles

Understanding the basics of cylindrical grinding is essential for engineers and technicians involved in precision machining operations. It provides them with valuable knowledge about how this process works and its applications across different industries.

By comprehending these fundamental principles, professionals can make informed decisions regarding equipment selection, tooling requirements, and optimal operating parameters to ensure efficient production processes that meet stringent quality standards.

The Cylindrical Grinding Process

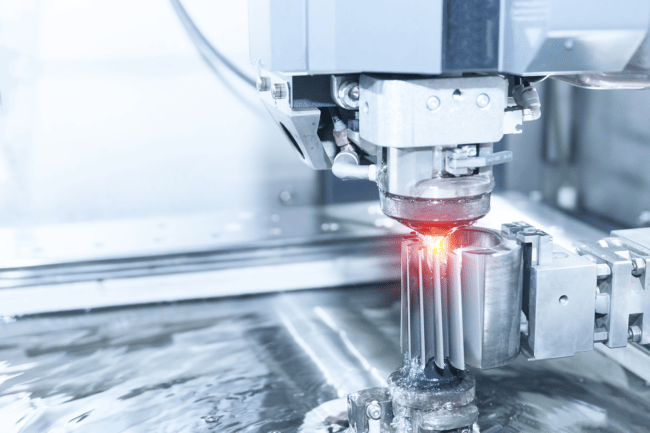

The cylindrical grinding process is a precise and efficient method used to shape and finish cylindrical workpieces by rotating them against a rotating grinding wheel. This operation is commonly used in the automotive industry for tasks such as engine crankshaft grinding, camshaft grinding, and cylinder block boring.

Rotating Grinding Wheel

The cylindrical grinding process is a precise and efficient method used to shape and finish cylindrical workpieces by rotating them against a rotating grinding wheel. This operation is commonly used in the automotive industry for tasks such as engine crankshaft grinding, camshaft grinding, and cylinder block boring.

To achieve fine surface finishes and tight dimensional tolerances, the cylindrical grinding operation involves several key components. First, the workpiece is securely held in place using steady rests or special fixtures to prevent any movement during the grinding process. This ensures that the workpiece remains stable and allows for accurate machining. Next, a control wheel is used to regulate the speed at which the workpiece rotates against the grinding wheel. The control wheel determines both the rotational speed of the workpiece and its position relative to the grinding wheel, enabling precise material removal. Additionally, coolant is often applied during cylindrical grinding to cool down both the workpiece and the grinding wheel, reducing friction and preventing overheating.

Overall, cylindrical grinding offers numerous benefits in terms of precision and efficiency when shaping and finishing cylindrical workpieces. By employing steady rests, control wheels, and coolant systems, manufacturers can achieve high-quality results with fine surface finishes that meet stringent specifications in industries such as automotive manufacturing.

Types of Cylindrical Grinding

There are various categories of cylindrical grinding that can be distinguished based on the type of workpiece being processed.

External Cylindrical Grinding

The first category is external cylindrical grinding, which involves the grinding of outer surfaces of a cylindrical workpiece. In this process, a rotating grinding wheel is used to remove material from the workpiece, creating a smooth and precise finish. This type of grinding is commonly used in industries such as automotive and aerospace for applications such as shafts and pistons.

Centreless Cylindrical Grinding

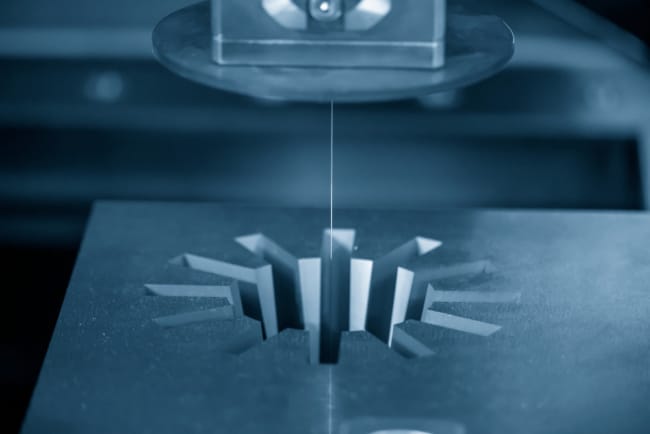

The second category is internal cylindrical grinding, where the focus is on the inner surfaces of a cylindrical workpiece. This process requires specialized equipment known as internal grinders, which use an even smaller rotating grinding wheel to reach inside the workpiece. Internal cylindrical grinding is widely used in industries like medical devices and hydraulic systems for applications such as tubes and bores.

Internal Cylindrical Grinding

Lastly, there is also a category called centerless cylindrical grinding, where no centers are needed to support the workpieces during machining. Instead, they are held in place by a regulating wheel while being ground between the rotating grinding wheel and the regulating wheel. This technique allows for high precision and efficiency in producing long rods or bars with consistent diameters.

Applications of Cylindrical Grinding

Applications of cylindrical grinding can be found in various industries, such as automotive, aerospace, medical devices, and hydraulic systems. Cylindrical grinding is a versatile process that allows for the precise shaping and finishing of complex components.

In the automotive industry, it is commonly used to manufacture engine components, such as crankshafts and camshafts, which require high levels of precision. Aerospace applications include the production of turbine blades and other critical aircraft components that need to meet stringent dimensional tolerances. In the medical device industry, cylindrical grinding plays a crucial role in the manufacturing of orthopedic implants and prosthetics.

The ability to achieve precise dimensions and surface finishes is essential for ensuring proper fitment and functionality of these devices. Additionally, cylindrical grinding finds application in hydraulic systems where it is utilized to produce hydraulic pistons with accurate dimensions for smooth movement within cylinders.

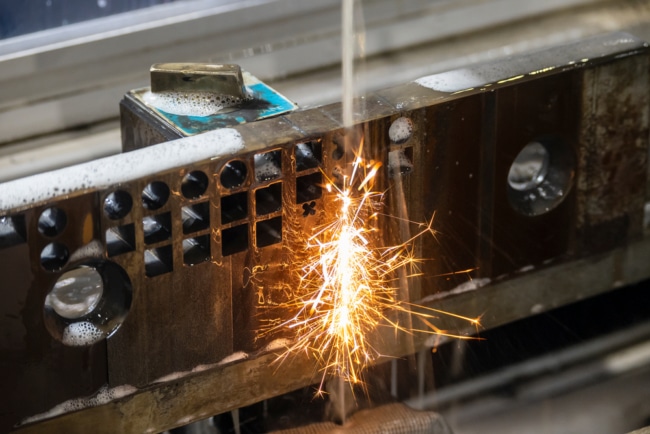

Grinding operations involve the use of a rotating grinding wheel that removes material from a workpiece by abrasion. During cylindrical grinding, the workpiece is held between centers or in a chuck while the rotating wheel grinds away excess material to achieve the desired shape or finish. The depth of cut can be adjusted based on specific requirements using feed mechanisms integrated into the grinder.

The fundamental design principles behind cylindrical grinding machines ensure repeatability and accuracy in achieving tight tolerances. These machines are equipped with precision spindles that provide high rotational speeds for efficient material removal while maintaining stability during operation. Advanced control systems allow for fine adjustments in cutting parameters such as speed, feed rate, and depth of cut to optimize performance.

Overall, applications of cylindrical grinding are diverse across multiple industries due to its ability to deliver precise shapes and surface finishes on complex components. This process enables manufacturers to meet strict dimensional requirements while ensuring optimal functionality in various applications ranging from automotive engines to medical devices and hydraulic systems.

Advantages and Disadvantages of Cylindrical Grinding

One of the key advantages of cylindrical grinding is its ability to achieve precise shapes and surface finishes on complex components, making it a highly versatile process in various industries. Cylindrical grinding uses a rotating grinding wheel to remove material from the workpiece, resulting in a cylindrical shape. This process is commonly used for finishing operations on parts that require tight tolerances and smooth surfaces. By carefully controlling the speed, feed rate, and depth of cut, cylindrical grinding can produce accurate dimensions and excellent surface finishes.

In addition to its precision capabilities, cylindrical grinding offers several other advantages. First, it allows for efficient removal of material from hard-to-reach areas or internal features that cannot be easily machined by other methods. The operation is carried out on strictly finishing machines designed specifically for this purpose. Second, cylindrical grinding can be performed on a wide variety of materials, including metals, plastics, ceramics, and composites. This makes it suitable for use in diverse industries such as automotive manufacturing, aerospace engineering, medical device production, and more.

Conclusion

In conclusion, cylindrical grinding is a precise and efficient process that involves the use of specialized machines to shape and finish cylindrical workpieces. It offers several advantages such as high accuracy, versatility, and the ability to produce complex geometries. However, there are also some disadvantages to consider, such as the need for skilled operators and the potential for thermal damage to the workpiece.

One idiom that can be used to emphasize the importance of cylindrical grinding is "the devil is in the details."This expression highlights the fact that even small variations or mistakes in the grinding process can have significant consequences on the final product. Therefore, attention to detail and careful monitoring are crucial during all stages of cylindrical grinding.

Overall, understanding the basics of cylindrical grinding is essential for those involved in manufacturing and engineering industries. By knowing the different types of cylindrical grinding, its applications, as well as its advantages and disadvantages, professionals can make informed decisions regarding its implementation in various projects. With proper knowledge and expertise, this versatile machining technique can greatly contribute to achieving high precision and quality in component fabrication.

Related Content

Need more information?

To see how A&M could support your next complex manufacturing project – simply call us, or use the form below.