Propulsion Systems

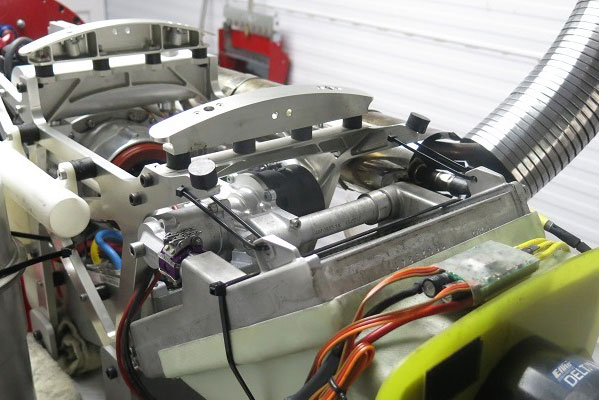

A&M have manufactured Wankel rotary engines for multiple customers and we developed our own engine cooling technology for a Midlands Aerospace Alliance NATEP (National Aerospace Technology Exploitation) project.

Our design engineers have over 25 years’ experience developing engine systems and in the past five years we have undertaken in-house R&D projects to design and manufacture a portfolio of propulsion systems for UAV /UAS applications.

We invested in a dedicated engine development unit with a Dynamometer for testing engine systems.

This facility has been used to develop our own products and can be hired by clients requiring engine testing support..

Sound proofed, highly computerised and fully supported including operational and environmental quality system, safety systems, extraction and high security.

Working with customer Non-Disclosure Agreements, our precision engineering achieves quality certifications:

- Quality Management AS9100 Aerospace

- NADCAP Aerospace AS7003

- BSI Quality Management EN9100:2016 covering EDM wire and spark erosion and CNC precision machining

- BSI Environmental Management System ISO 14001:2015

We have full in-house capabilities to design, manufacture, assemble and test engine systems

- 60 CNCs – Spark & wire EDM; 3,4, 5 Axis CNC Milling & Turning

- Metrology Inspection

- Laser welding, Fabrication

- Toolmaking, sub-assembly

- 3D Printing, laser scanning

- Reverse engineering

- We integrate with our supply chain for the engine electronics and plating

Early in 2021, a non-European customer successfully commissioned A&M’s proprietary UAS (unmanned aerial system) system.

We manufactured a mock unmanned aerial vehicle fuselage to complete a verification installation of the system. The system travelled thousands of miles in secure packaging to reach our customer and successfully started first time.

This system is uniquely able to deliver 4hp of electrical power running on kerosene whilst providing thrust with its low weight, low vibration operation.

Our flexible propulsion systems offer unique functionality:

- Kerosene operation from cold start (tested to minus 27 degrees Celsius)

- Highest power density on the market

- Eliminating seal wear by using ceramic combustion seals

- AS9100 Manufacturing quality standards

- High hybridisation if required

- Currently in batch production runs

- Lightweight, compact

- Very low NVH (noise, vibration, harshness)

- Gasoline operation if required

- 2hp and 9-10hp continuous power (peak 14 hp) versions

- Fully electronically controlled via CAN bus including altitude compensation.

- Mature, integrated, complete propulsion systems

- Certified for use outside of designated flight zones, as part of an aircraft system, by a European customer