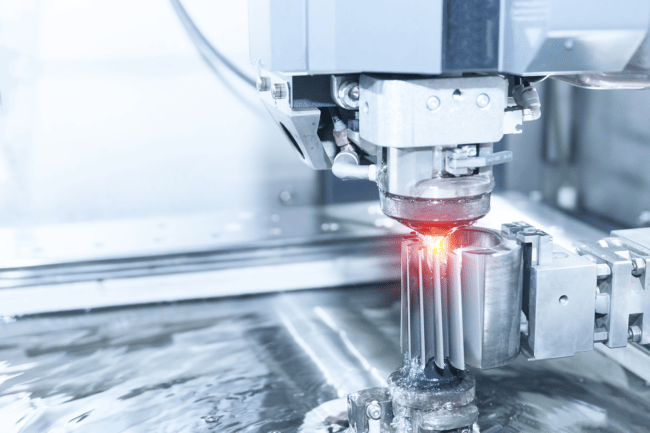

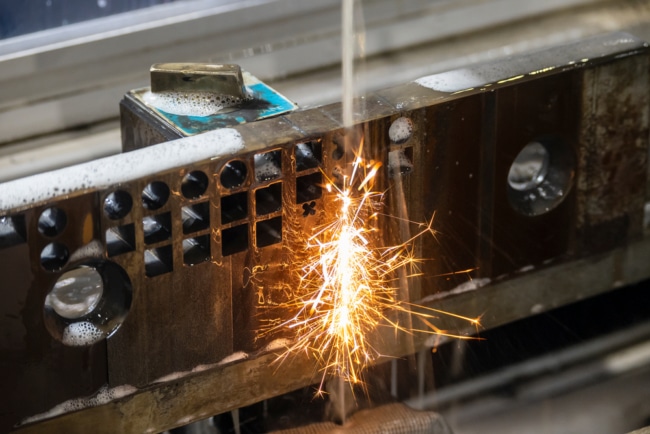

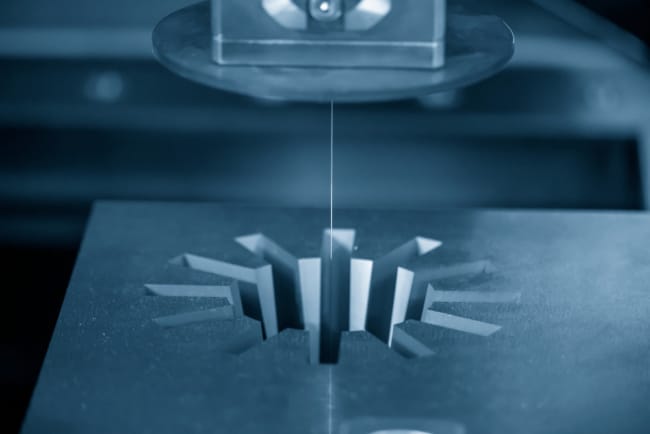

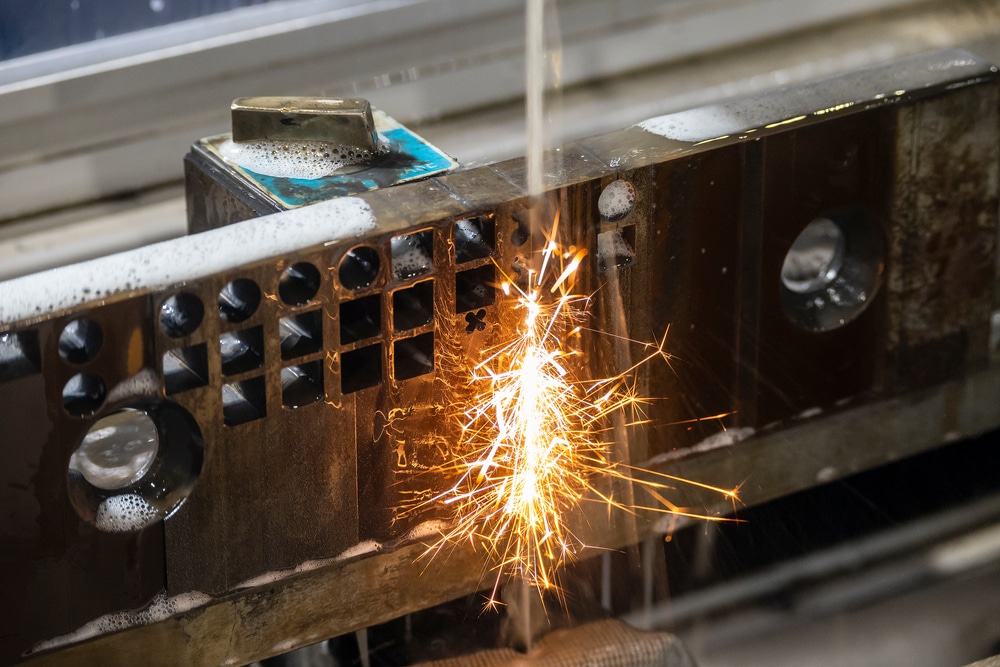

Spark Erosion, also known as electrical discharge machining, is a manufacturing process which creates a specific shape using electrical discharges (sparks). Spark erosion removes material from a piece with current discharges between two electrodes that are separated by a dielectric liquid that is subject to voltage. The dielectric fluid acts as a conductor and a cooling agent during the sparking process.

What is EDM Spark Erosion Used For?

EDM spark erosion is used for a variety of complex operations, with multi-feature sparking available across one operation. This incorporates multi-axis erosion which cuts in three axes simultaneously.

Spark erosion machinery boasts technology that enables use on a range of multiple electrodes materials, including copper and graphite, so that pieces made of delicate metals such as Inconel and titanium can be worked.

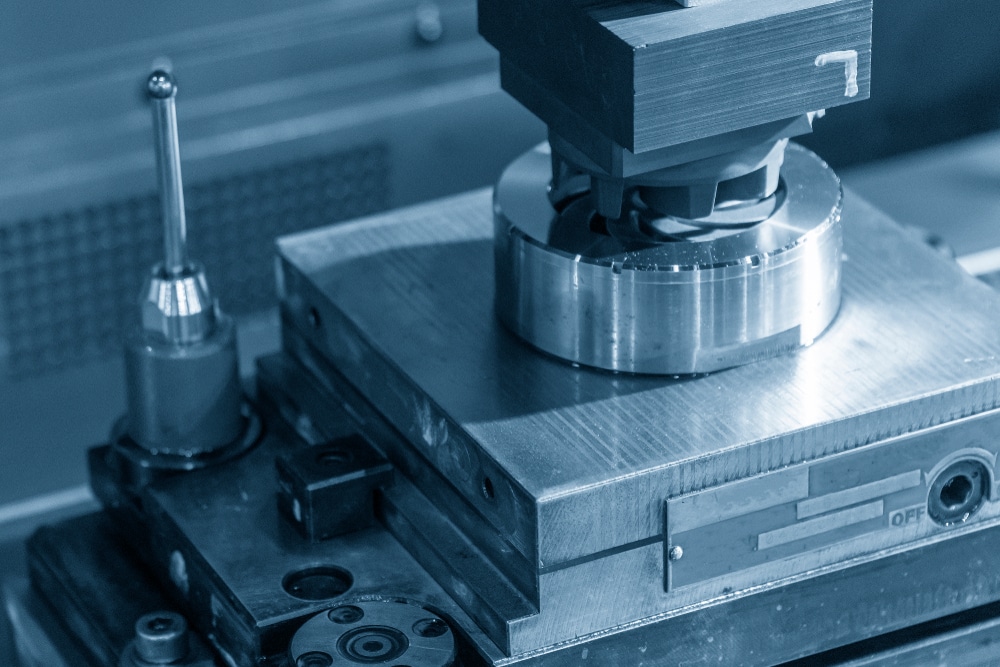

At A&M, our spark eroders have C-Axis capabilities, meaning electrodes can be spun in order to achieve higher precision at greater tolerances.

EDM Spark Erosion Process

Two electrodes, comprised of the tool-electrode and the workpiece-electrode, produce a series of rapidly recurring current discharges. In this process, the tool and the workpiece must not make physical contact. Instead, it is reliant on the electrical discharges removing material from the workpiece in accordance with the dimensions required.

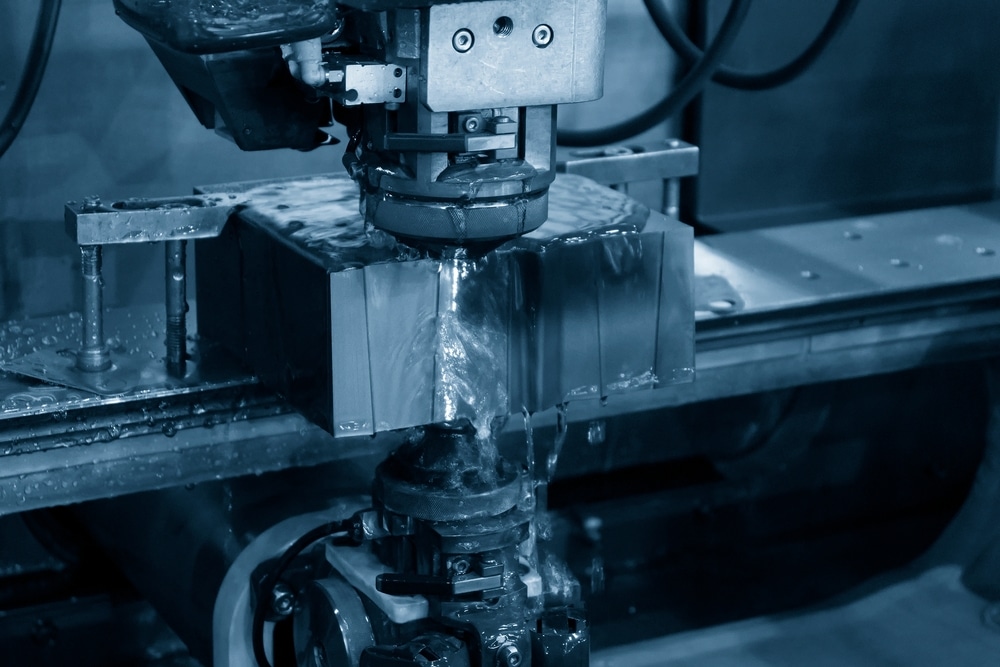

The electrodes are separated by a dielectric liquid. Once the voltage is increased, the intensity of the electricity between the electrodes expands, causing the dielectric liquid to break down, leaving an electric arc in its place. This enables material to be removed from the electrodes. New dielectric liquid is formed after the current is stopped, thermal shocking the metal and creating a hot plasma on the workpiece which moulds the piece into a shape opposite to that of the electrode.

How Does a Spark Erosion Machine Work?

A spark erosion machine contains the electrodes and dielectric fluid required for the process, allowing the flushing to take place, which removes the chippings from a workpiece.

Advantages of Spark Erosion

One of the main advantages is the versatility of spark erosion. The process requires exact shapes and specifications to be cut on a range of jobs, from small jewellery to aircraft landing equipment or cutting a keyway hinge on a submarine hatch. Spark erosion machines can perform any operation necessary for a client.

Another advantage for spark erosion is the flexibility it provides for lights out operations, with jobs able to continue to run unmanned over the weekend.

Either hardened or delicate materials can be worked, due to the lack of contact between the electrode and the workpiece. Thus ensuring no damage on the finished piece, which also means a good surface finish is achieved.

A&M provide a range of different size Sodick spark eroders and our twenty years’ experience has seen us work thousands of parts for use in cars, planes, boats and submarines and tooling to manufacture household and medical products.

We use both SYSTEM 3R and EROWA, the two main spark erosion machine work holding systems. We also use EDM sparking to create precision contours in a wide range of conductive materials including graphite, tungsten and Inconel aerospace components and manufacturing different sizes of own design rotary UAV system engines.

Disadvantages of Spark Erosion

These include the need for specialist skills and experience to program and operate the latest technology spark erosion machines to achieve their full potential. Hence, training or recruiting operators. This could also see a decrease in the importance of manual skills.

Spark erosion is a long operation and is therefore not the most time efficient. There are no manufacturing short cuts for it, which can be frustrating for either the operator or the client.

The workpiece must be conductive or it cannot be eroded, so there is a smaller pool of materials which can be worked. Tools can become worn more quickly due to the power needed to support the spark erosion procedure.

For more information about spark erosion or any other EDM services, please get in contact with A&M today and we will be happy to answer any questions you have.

Applications of Spark Erosion

Mold and Die Making:

Extensively used in mold and die making industries to create complex shapes and cavities in hard materials like steel, titanium, and carbide. It allows for precise and intricate detailing, which is essential in the production of molds and dies for various applications.

Medical Industry:

Utilized in the medical industry for the production of surgical tools, implants, and medical device components. It allows for the machining of complex and small-scale parts with high accuracy, meeting the stringent requirements of the medical field.

Electronics and Tooling:

Used for manufacturing precision components in the electronics and tooling industry. It helps in producing intricate features, such as small holes, slots, and notches, in materials like tungsten carbide, which are commonly used in electronic devices and precision tools.

Aerospace Industry:

Widely used in the aerospace industry for manufacturing turbine blades, engine components, and other critical parts. It enables the production of intricate shapes and profiles in high-strength materials, ensuring the required precision and quality.

Automotive Industry:

Spark erosion finds applications in the automotive industry for manufacturing components like gears, engine parts, and injection molds. It allows for the production of intricate shapes and profiles in hardened materials, ensuring excellent dimensional accuracy.

Energy Industry:

Employed in the energy sector for manufacturing components used in power generation equipment, such as turbines and generators. It enables the production of complex shapes and profiles in heat-resistant materials, ensuring high efficiency and reliability of the equipment.

Conclusion

Spark erosion, also known as electrical discharge machining, is a versatile manufacturing process that is used in various industries such as mold and die making, medical, electronics, aerospace, automotive, and energy. It allows for the production of intricate shapes and profiles in hard and delicate materials with high precision and accuracy.

While there are some disadvantages to spark erosion, such as the need for specialized skills and longer operation time, its advantages, including the ability to work on a wide range of materials and achieve a good surface finish, make it a valuable process for many applications.

Related Content

Need more information?

To see how A&M could support your next complex manufacturing project – simply call us, or use the form below.