Toolmaking

A&M provide precision toolmaking to bespoke specification and provide a fast response tool and die repair and replacement machinery parts service.

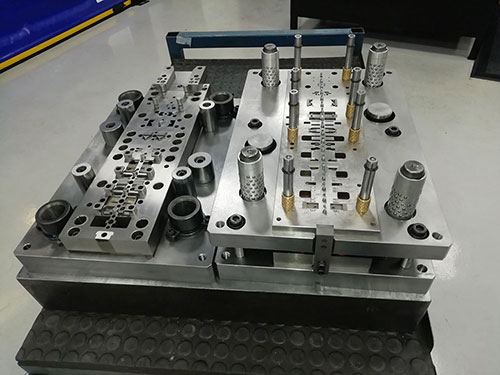

Our team has extensive experience manufacturing jigs, fixtures and press tools including:

Multi-stage tools

Progression tools

Blanking tools

Precision Jig Manufacturing

A class tooling for automotive skin panels

Single stage Form dies

Cam cutting / Form dies

Hot press forming dies

CMM inspection of assembly fixtures to 10 microns

Production assembly tooling and repairs

Our design for manufacture and reverse engineering capabilities enable us to be a design partner from early development.

We offer a full package, taking your damaged tools and using our 3D laser scanning and CMM to produce working CAD models to fully reverse engineer the tools.

Alternatively, we can use laser welding to repair parts, with all our work accredited to BSI Quality Management EN.9001.2016 standard.

Contact us to discuss our toolmaking and fast response tool and die repair capabilities.

Toolmaking Frequently Asked Questions

What is toolmaking?

Toolmaking is the process of creating or manufacturing tools that are used for various purposes. These tools can be handheld, power-operated, or machine-based, and they are designed to assist in tasks such as cutting, shaping, drilling, fastening, measuring, and more. Toolmaking involves a combination of skills and techniques, including metalworking, machining, forging, casting, welding, and precision engineering. It requires expertise in understanding the function and requirements of the tool, selecting appropriate materials, and using various tools and machines to shape and assemble the components. Toolmakers play a crucial role in various industries, including manufacturing, construction, automotive, aerospace, and many others, as they create the tools necessary for production and maintenance processes.