We feature in the latest edition of the Black Country Chamber Prosper magazine on our approach to developing apprentices.

https://www.prospermagazine.co.uk/sector-06

THE APPRENTICE - YOU'RE HIRED!

https://www.prospermagazine.co.uk/sector-06

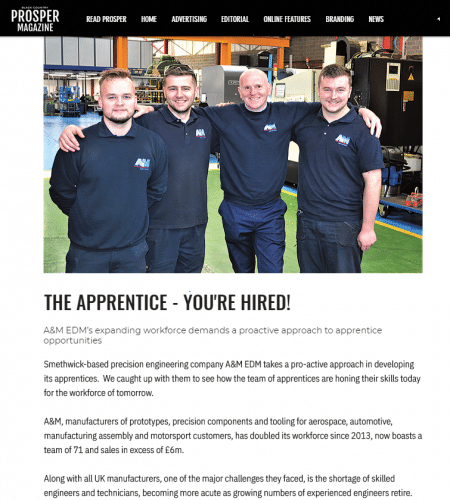

A&M EDM’s expanding workforce demands a proactive approach to apprentice opportunities

Smethwick-based precision engineering company A&M EDM takes a pro-active approach in developing its apprentices. We caught up with them to see how the team of apprentices are honing their skills today for the workforce of tomorrow.

A&M, manufacturers of prototypes, precision components and tooling for aerospace, automotive, manufacturing assembly and motorsport customers, has doubled its workforce since 2013, now boasts a team of 71 and sales in excess of £6m.

Along with all UK manufacturers, one of the major challenges they faced, is the shortage of skilled engineers and technicians, becoming more acute as growing numbers of experienced engineers retire.

This demographic time bomb has its roots in the 1980s when manufacturing suffered a recession and was perceived as an unattractive career, resulting in young people turning away from apprenticeships and factories towards degrees and service sector jobs.

A&M began its Apprenticeships in 2013, selecting individuals with creative enthusiasm and STEM qualifications. Using experienced staff as mentors on the programme which starts with basic engineering as its foundation. Apprentices then move onto practical skills for different operations such as milling, turning, CNC operation and spark and wire eroding.

​A&M works in partnership with Dudley College,

as its chosen academic training provider for Level 3 Apprenticeships and HNC. In recent years A&M has trained over a dozen individuals, with four currently on apprenticeships, three progressing to the Dudley College HNC Higher Apprenticeship programme and three recently completing their HNC qualifications.

Research by Make UK, the organisation representing UK manufacturing revealed:

· UK companies need 124,000 skilled engineers in 2020

· A projected shortfall of 59,000 engineers

· 46% of manufacturers reporting recruitment difficulties in 2019

Three A&M employees gave their views Joe Siviter, aged 18 is in the final year of his Manufacturing Engineering Apprenticeship.

Joe now works on electro-discharge machining spark erosion and has already worked on hundreds of jobs for diverse customers.

Joe said, "Combining the theory I learn at Dudley College with on the job training has developed my skills much faster. My favourite job is spark eroding a component for a product with over 200 years of heritage.”

Joe plans to progress to a higher HNC and then a degree. His long-term aim is to focus on aerospace engineering design. He said, "My Apprenticeship gives me relevant work skills and qualification.

Schools should do more to encourage apprenticeships as an alternative to the university route.”

Jack Kemp, aged 24, has just completed his Apprenticeship; he wants to continue learning by taking a part-time engineering degree.

"Most of the college work is theoretical, including mathematics, material properties and CAD/CAM design. I’ve put this into practice, working in different parts of the company. I’ve CNC milled parts for a rotary engine and machined components to precise tolerances for a motorsport customer.”

David Tomkins aged 23, was one of A&M’s first apprentices in 2013 and is completing his HNC. A memorable job for David was spark eroding an injection mould tool for a major manufacturer of razor blades to a tolerance of 5 microns.

David’s clear on the advantages of an Apprenticeship "I earn a good wage and have six years’ engineering experience in a job which I’ve been trained to do. I completely support apprenticeships and believe my experience gives me an edge over graduates.”